Pulley Protection Splint

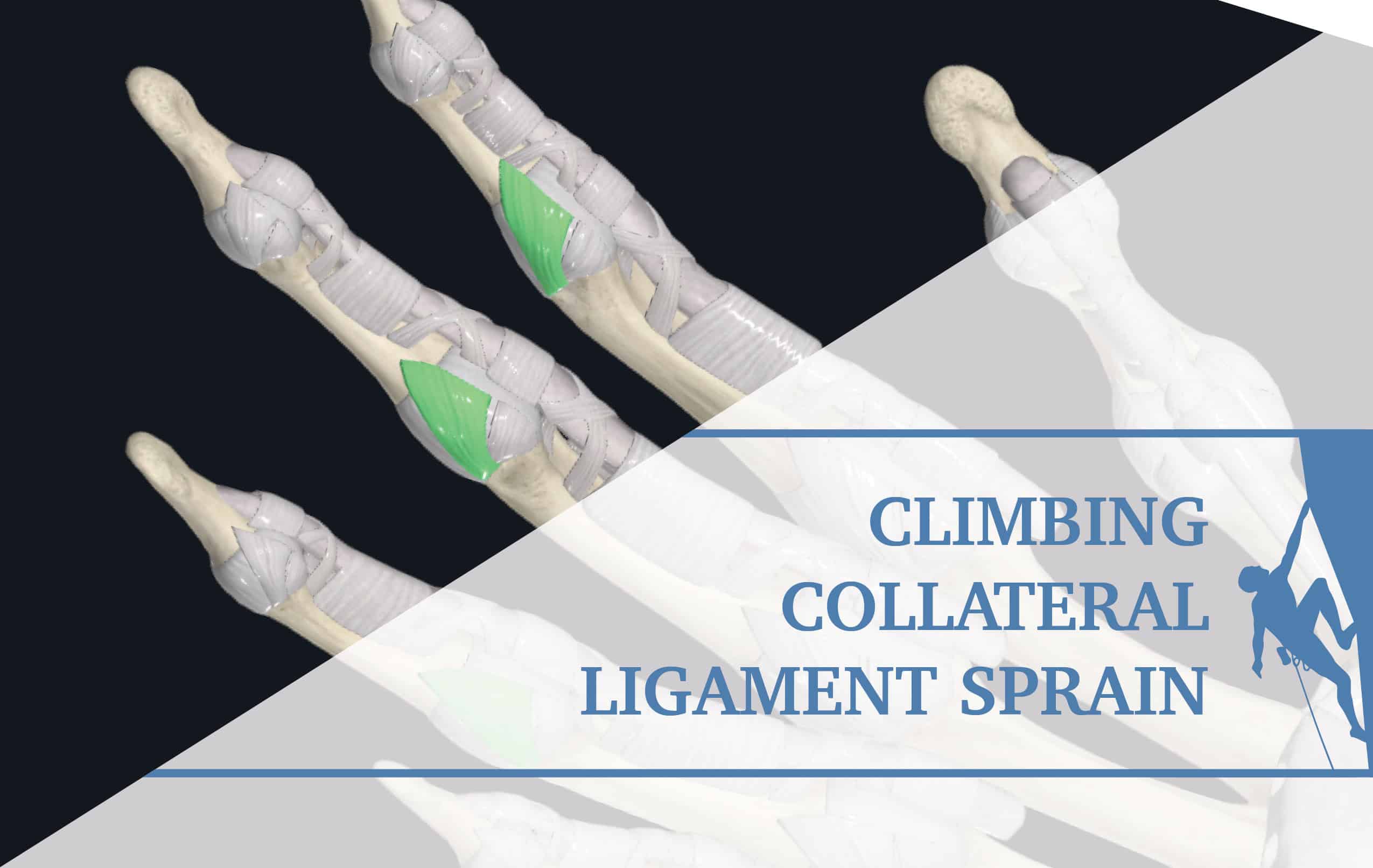

This article will take you through a step-by-step process of how to fabricate a pulley protection splint for a rock climber with a grade II or III pulley sprain. The purpose of the article is to educate the climber as well as the medical practitioner on the details of constructing the splint.

Special Thanks:

This article would not have been possible without the guidance, expertise and recommendations from highly respected researchers, medical doctors and surgeons who specialize in climbing injuries. The techniques described below were modified from the research study by Micha Schneeberger B.S. and Dr. Andreas Schweizer M.D. titled “Pulley Ruptures in Rock Climbers: Outcome of Conservative Treatment With the Pulley-Protection Splint-A Series of 47 Cases.” Expert opinion from discussions with Dr. Volker Schöffl M.D. further shaped the technique and procedures to make a Pulley Protection Splint (PPS) that are described in this article. Additional thanks to Dr. Liz Souza DPT, CHT for her guidance.

Complete Video:

The complete video of how to make a pulley protection splint is below. It is approximately 22 minutes. You can view the video in its entirety, or reference the clips within the article that are associated with each step of the process.

Pulley Sprain Introduction:

Dr. Jared Vagy DPT, author of the best selling book Climb Injury-Free and Dr. Matt DeStefano DPT teamed up to teach medical practitioners how to make pulley protection splints with the help of three time youth national champion Ross Fulkerson. A PPS is an effective treatment for acute grade II or III pulley ruptures since it approximates the flexor tendons to the bone, as in holds them closer, to take stress off the injured pulley. A study by Dr. Andreas Schweizer and Micha Schneeberger, published in the Journal of Wilderness and Environmental Medicine, evaluated the effectiveness of using a PPS after grade III complete pulley ruptures in rock climbers. The results showed almost 90 percent of the climbers who wore the splint returned to their previous climbing level after approximately eight months.

While you’re likely familiar with taping, a PPS differs in design and function. With tape, it’s difficult to achieve enough force to significantly change bone-tendon distance because it would cut off your circulation, especially if you wear it all day. The PPS, however, includes collateral bulges on the sides of the ring. These allow strong compression of the finger while giving adequate space to protect the nerves, arteries, and veins from being compressed. Additionally, it’s made from moldable plastic, which is more rigid than tape. Thus, it can be applied for longer durations with better compression. Medical experts recommend you wear this splint throughout the day (23-plus hours) for six to eight weeks to take stress off the injured pulley and allow it to adequately heal.

Items Recommended:

Below is a list of all items involved in the splinting process. Depending on your budget and professional setting, you can use as few or as many as you feel are appropriate. The set up cost can range anywhere from $40 – $400 depending on what you can reuse (frying pan, tongs, scissors spatula, etc…) and what you need to buy. For medical providers in the clinical environment recommend items are notated with an asterix. If you are a climber and not a medical provider, you likely have most of the equipment available and can substitute with everyday gear.

Dirtbag Tip:

If you are a climber and looking to make this on a budget, skip the equipment recommendations and try this: Use a pot instead of the skillet, instead of a thermometer just gradually increase heat until the plastic becomes malleable, skip the heat gun and use sandpaper, forget the mandrel – just wrap it around your finger, skip the spatula and use free chop sticks. You get the point…basically everything can be substituted for a dirtbag pulley splint set up – well except for the splinting material and tape.

| Item | Price |

|---|---|

| Northcoast Medical | |

| Orfit Prism 1/8 inch or Rolyan Splinting Original Solid 1/8 inch | $8.50 – $82.50 |

| Splint Pan Netting | $17.95 |

| Thermometer | $29.95 |

| Curved Scissors | $29.95 |

| Precision Heat Gun | $60.99 |

| Amazon | |

| Presto 06620 11-Inch Electric Skillet* | $34.94 |

| Double Sided Mounting Tape | $5.84 |

| Mandrel* | $19.99 |

| 16.2 Gauge Extension Cord | $7.46 |

| Leukotape* | $7.60 |

| Utility Knife* | $14.48 |

| Needle Nose Pliers | $6.28 |

| Clamp Vice | $14.99 |

| Moleskin | $9 |

| Black Diamond | |

| Honnold Spatula | $15 |

| Supplies You Likely Own | |

| Paper Towel | $0 |

| Pen | $0 |

| Hand Soap | $0 |

Having the specialized materials makes it easier and quicker to fabricate the splints, but the most important thing is that you practice as often as possible. We recommend making at least 25 practice splints before you begin molding splints for your rock climbing patients.

This article demonstrates how to fabricate a pulley protection splint for the A2 pulley using 1/8’’ or 3.2 mm thermoplastic material. If you would like to fabricate a splint for the A4 pulley with similar materials used in Schweizer’s study, it is recommended that you use 3/32’’ or 2.4mm thermoplastic material.

Make the Mandrel, Make the Thermoplastic Cut Out, Prep the Pan and Heat the Water

Below if the step-by-step instructions on how to make the modified mandrel, cut out the thermoplastic material, prep the splint pan and heat the water so that you can fabricate a pulley protection splint.

Make the Mandrel

- There must be raised columns on each side of the mandrel in order to create a splint that has space for the vasculature of the finger on the lateral aspects.

- Use double-sided tape to attach the wire to the mandrel. Make sure that you line up the tape and wire so that they are directly opposite from each other on the mandrel.

Make the Thermoplastic Cut Out

- Roughly measure long 10cm sections of the bigger sheet, and then divide each 10 cm section into ~2.5cm sections. These 10×2.5cm rectangles will be used as the stock to make into your PPSs.

- Score the splint material using a sharp, rigid blade (box cutter shown here.) You will have to re-score the same line a few times.

- After scoring the sections (larger 10cm sections first,) you will then bend and snap the thermoplastic along the scored line. After long 10cm sections are separated, cut these into ~2.5 cm sections.

Prep the Pan

- Cut the splint pan netting to the pan dimensions. The netting is used to keep the thermoplastic from sticking to the pan.

- Clip the thermometer to the edge of the splint pan

Heat the Water

- Fill splint pan 2 inches deep with warm water

- Add a few drops of hand soap to help with decreasing the stickiness of the material

- Heat the pan to 160 degrees

- Keep the water at this temperature. The smaller the pan, the quicker water evaporates but the quicker it heats.

Measure the Finger

- Measure the injured finger with a strip of paper towel that is roughly 1.5cm wide and 10cm long. (For people with longer fingers you may need to choose 2 cm wide. This will be the width of your PPS.) Overlap the paper towel strip and mark starting end with a pen.

- **Using paper towel is better than a normal sheet of paper because the paper towel is easier to manipulate.

- SAVE THIS PAPER TOWEL STRIP.

- Find mark estimate on mandrel

- Use your paper towel on the mandrel to find what level you will use to wrap the splint around. This level will be where the paper towel wraps around and almost touches end. Or you can measure by touching each end of the paper towel to the edges of the plastic strip on the sides of the mandrel.

- Save this mark on the mandrel for molding the soft thermoplastic around in a later step.

Heat the Material for the First Time

- Put splinting material in the pan for approximately 2 minutes or until the material becomes pliable

- Wait until the plastic becomes very pliable.

- Remove the thermoplastic cut out from the pan and immediately place the paper towel template onto the thermoplastic cut out.

- Cut around the paper towel to create a piece of thermolastic that is the exact size and shape of the paper towel template.

Heat the Material for the Second Time

After you’ve cut the thermoplastic to be custom sized, put it back in the heating pan for approx 45-60 more sec.

- Pull out the thermoplastic strip and place it around the mandrel at the level you marked earlier. Wrap around just like you wrapped the paper towel template, until the ends of the plastic strip are separated only by the plastic side bar.

- Gently mold the thermoplastic strip around the mandrel taking care to form the splint over the plastic side bars on the mandrel. Don’t press too hard, or the thermoplastic may stick to the mandrel.

- Let the plastic harden on the mandrel for approx 60-120 sec, and then gently prise it off taking care not to deform the ring too much. Once there is minimal space between the thermoplastic and the mandrel, you can slide it off instead of opening the ring like a book.

Heat the Material for the Third Time

- Dip the edges of the ring into the hot water until the become pliable and cut any excess length off of the pulley protection splint

Heat the Material for the Fourth Time

Now you have a PPS in your hand, but you need to smooth the edges of the plastic. Otherwise there will be sharp edges that can damage the patient’s skin.

- Use the stationary heat gun in the vice to warm the edges of the PPS. (CAUTION: do not hold the splint too close or it will burn/melt. Also gently use pliers to hold the splint to avoid burning your fingers.)

- Gently smooth all edges and corners of the PPS using your finger tips. Repeat this step until all rough edges are smooth.

- Test the sizing of the splint on the patient’s finger. Place PPS on the distal-most aspect of the proximal phalanx (for A2 pulley injury.)

Make the Splint Comfortable

- Add moleskin to the dorsal portion of the splint to decrease the chances of skin breakdown. You can add it to both sides but this dorsal portion is more likely to experience more sheer force.

Securing the PPS Closed

This is the most important step for proper use of the PPS. If the splint is made perfectly, but the patient does not secure the splint tight enough, then the PPS is not doing its job it was made to do.

- Place PPS on the distal-most aspect of the proximal phalanx (for A2 pulley injury) right up against the joint line. When sizing and adjusting, ensure that the PPS does not drift proximally with movement.

- Use leukotape to secure the PPS closed. You must use leukotape because other tapes lack the tensile strength. The tape should be reapplied at least once per day, but at least recheck to make sure the tape and closure is tight. Tape does stretch over time.

- To close the splint, place a strip of leukotape tape on the palmar side of the splint. Starting the tape from the palmar side and pulling upward ensures an upward directed force mimicking the pulley.

- Taping Steps:

- Stabilize with ipsilateral thumb

- Stabilize the dorsal side of the splint with middle finger while pulling tape taut with contralateral thumb/index, and increase closure with contralateral ring finger.

- Seal the splint closed. Ensure that the dorsal/palmar lips are indeed closed tight when you seal the tape. REMEMBER: This is the most important step.

- Taping Steps:

- To close the splint, place a strip of leukotape tape on the palmar side of the splint. Starting the tape from the palmar side and pulling upward ensures an upward directed force mimicking the pulley.

Advisory

- When fasting the pulley protection splint to the finger, make sure that you fully educate the climber on how tight to fasten so that it does not occlude blood flow. If the finger has a capillary refill of less than 2 seconds, looses circulation or has temperature changes, immediately remove the splint and reapply with less tension once blood flow, temperature and sensation return to the finger.

Alternative Method

- Rather than using the mandrel to size the PPS, you can tape the wire to the sides of your finger and mold directly to the finger. This allows for a custom fit of the splint to the patient’s finger.

- The benefit is that you can further customize to material to the patients finger without the need of the extra steps using the mandrel

- The drawback is that it takes more care and precision to mold directly to the finger

Closing Remarks

- If you are a medical practitioner feel free to use this article and the associated videos to learn or refine your thermoplastics skills

- If you are a climber and you have a finger injury, get it checked out and feel free to share these videos with your medical practitioner

Additional Considerations

- Splinting Material

- The recommended splinting material is 1/8″ PRISM material that has a moderate resistance to stretch. However, there are some scenarios that may require a more pliable and material with minimal resistance to stretch. In this case, Orfit Classic 1/16 inch Smooth can be used.

Use a tape measure ahead of time to objectively monitor swelling progress but not needed to measure for fit.

- The recommended splinting material is 1/8″ PRISM material that has a moderate resistance to stretch. However, there are some scenarios that may require a more pliable and material with minimal resistance to stretch. In this case, Orfit Classic 1/16 inch Smooth can be used.

- Patient Comfort

- If the patient reports discomfort with the PPS, there are several possible modifications that can be made to improve overall comfort.

- If pain is felt on the dorsal aspect of the finger:

- Add thicker moleskin to the PPS

- Create a rounded, wider surface area on the PPS where it sits on the dorsum of the finger

- If pain is felt on the palmar aspect of the finger:

- Check capillary refill and if greater than two seconds, decrease the amount of pressure in the PPS by loosening the tension of the Leukotape

- If pain is felt in the webspace of the fingers

- Make sure that you heated and rounded all edges

- If pain is felt on the dorsal aspect of the finger:

- If the patient reports discomfort with the PPS, there are several possible modifications that can be made to improve overall comfort.

Final Thoughts:

There are many ways to fabricate and mold thermoplastics. The methods in this article are a combination of research recommendations and clinical practice. However, if you have some great ideas, or if you feel something was left out of the article, post a comment to add to the discussion!

References:

- Schoffl VR, EINWAG F, STRECKER W, Schoffl I. Strength Measurement and Clinical Outcome after Pulley Ruptures in Climbers. Med Sci Sport Exerc. 2006;38(4):637-643. doi:10.1249/01.mss.0000210199.87328.6a.

- Schoffl VR, Schoffl I. Injuries to the Finger Flexor Pulley System in Rock Climbers: Current Concepts. J Hand Surg Am. 2006;31(4):647-654. doi:10.1016/j.jhsa.2006.02.011.

- Schneeberger M, Schweizer A. Pulley Ruptures in Rock Climbers: Outcome of Conservative Treatment With the Pulley-Protection Splint-A Series of 47 Cases. Wilderness Environ Med. 2016;27(2):211-218. doi:10.1016/j.wem.2015.12.017.

- Gnecchi S, Moutet F. Hand and Finger Injuries in Rock Climbers. Cham: Springer International Publishing; 2015. doi:10.1007/978-3-319-16790-9.

- Zafonte B, Rendulic D, Szabo RM. Flexor Pulley System: Anatomy, Injury, and Management CME INFORMATION AND DISCLOSURES. J Hand Surg Am. 2014;39:2525-2532. doi:10.1016/j.jhsa.2014.06.005.

- Hochholzer T, Schoeffl V, Zapf J. One Move Too Many — : How to Understand the Injuries and Overuse Syndroms of Rock Climbing. Lochner; 2003.

- Schoffl I, Einwag F, Strecker W, Hennig F, Schoffl V. Impact of taping after finger flexor tendon pulley ruptures in rock climbers. J Appl Biomech. 2007;23(1):52-62.

- Disclaimer – The content here is designed for information & education purposes only and the content is not intended for medical advice.

Thanks for the tutorial. I find it interesting you don’t mention anything for A4 PPS fabrication. Schweizer mentions using thinner (2.4 mm) thermoplastic.

Also, to avoid having to heat the thermoplastic so many times for cutting and trimming, I recommend Wiss Shears (https://www.homedepot.com/p/Wiss-10-in-Shop-Shear-W10TM/205034451) to do the cutting and trimming without heating. I found this much easier and quicker.

Cheers!

JJ

Hey JJ,

Glad you enjoyed the tutorial. Since A2 injuries are the most common and we demoed the splints in the videos for A2, I didn’t include the thicknesses for A4 in the original post. I have now gone in and updated it with that information.

Also, great tip on the shears. It is a good budget option. I typically use the curved shears mentioned in the article with the steps that I outlined to get the smoothest edges, but there are many ways to fabricate, so the more options the better!

This is awesome. Thank you! My DPT wife made me a splint and the protocol seems to be working so far.

Hey there! What would you think about 3d-printing a splint? I think, that could be an awesome and easy method (since I happen to have a 3d-printer…)! But I’m not sure how to get the appropriate shape of the splint, has anybody a good idea about it? Let me know, fuechsl@gmx.ch. Cheers, Martin

Hey Martin,

I mostly 3D print them now. A while back I started experimenting with the design (with my 13 year-old nephew who is a 3D printing whiz!), see the clip below

https://www.instagram.com/p/CdeRDRtB-Rm/

Now I have them professionally printed in various sizes for my patients.

Hi Martin,

Where should you position the splint for an A4 injury?

Should it be the distal end of the middle? Or the proximal end of the middle?

Cheers,

George

Proximal end of the middle phalinx. However, we are investigating right now in a research study whether or a splint is necessary for A4 pulley injuries. But for now, best to splint.

Cheers for the quick response

Hi Dr.! I have loved reading your article; it’s excellent. I would like to make my own pulley splint, but I see that the prices of Orfit Prism 1/8 inch or Aquaplast Original Solid 1/8 inch are quite high (starting from $80). Do you know of any more affordable alternatives? Greetings and thanks for the incredible content you provide us.

Cheers,

Fred

I found a smaller version of 1/8’’ splinting material on amazon and have linked it in the supplies and also below:

https://amzn.to/3RBGQlh